Tanks a lot!

Famously, Henry Ford said, “You can have any colour as long as it’s black.” That was then. Thankfully, diving has come a long way from the day when a shop owner would smile and tell you cheerfully, “You can have any tank you want, as long as it is a steel-72.”

Scuba cylinders, or ‘tanks’ in the parlance, have multiplied considerably over the years and we celebrate that choice in its various manifestations:

- Material, most commonly steel or aluminum

- Size or capacity, typically measured in cubic feet

- Pressure, another imperial measure in pounds per square inch

- Purpose, for specific sport diving activities and techniques

There may be all sorts of exotic compounds out there from stainless steel to spun glass from which high-pressure cylinders can and are being made but for most us, the choice is steel or aluminum.

There may be all sorts of exotic compounds out there from stainless steel to spun glass from which high-pressure cylinders can and are being made but for most us, the choice is steel or aluminum.

Here at DIVER we’re all for a two to three hour dive duration tank the size of a lunch box thermos bottle. But maybe the solution is in rebreathing, which you can read up on elsewhere in this issue.

Still, size does matter because today there’s a dazzling selection on offer from cute little 1.4 cubic foot pony bottles to the mother of all dive cylinders offering almost 150 cubic feet of breathing gas.

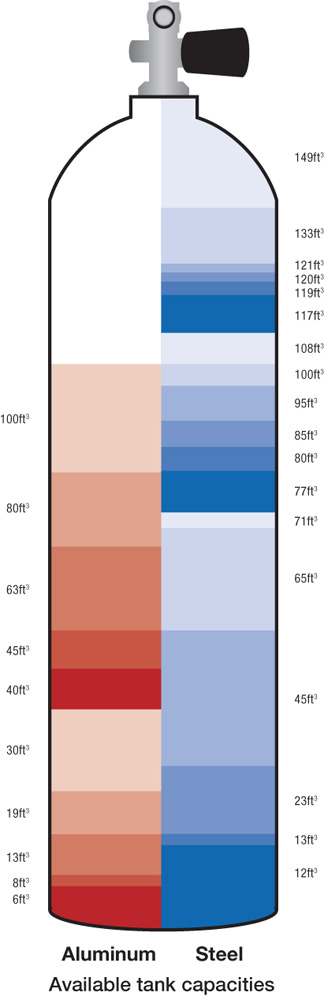

And trust us, there are more choices than you’d reasonably expect. From our research we’ve determined that steel tanks are fabricated in these sizes – 12, 13, 23, 45, 65, 71, 77, 80, 85, 95, 100, 108, 117, 119, 120, 121, 133, 149, and this bunch excludes various pony bottles. If it’s an aluminum cylinder you’re after then the choice appears smaller – 6, 8, 13, 19, 30, 40, 45, 63, 80, 100 – but we’re still impressed.

Tank pressure is an element of the equation that lives in a symbiotic relationship with compressors.

Ergo, the advent of compressors capable of pumping to higher pressures allowed for the fabrication of a wider range of tanks. The good old steel 72 is a “low pressure” tank at 2250 pounds per square inch (psi). Today’s cylinders fall into three pressure groups:

Low pressure – 2400 to 2640 psi

Standard pressure – 3000 psi

High pressure 3300 to 3500 psi

Simply, the higher the pressure the greater the gas capacity the tank can hold. Know the limit of the compressor(s) at your local dive shop before you buy a tank.

In the debate of aluminum versus steel, issues consider the weight of each, filled and empty, and how each affects buoyancy during a dive; typically, steels remain negative, aluminum becomes positive. Is the service life of one material better than the other? Some shops have stopped filling aluminum tanks 15 years and older. Some steel tanks are still in service 40 years later.

So what scuba cylinder is right for you? Consider your physical size, the dive environment and the kind of diving you intend. A big tank on a small frame can be restrictive. If you’re slight then a really heavy cylinder can also work against you. A larger capacity tank is a better choice for cold water diving. And what of diving preferences? There’s everyday sport diving with its subsets that include overhead environments such as shipwrecks. There’s technical diving that involves descending to depths well beyond sport limits. Cave diving can combine overhead and depth. Some prefer a tank on their back but sidemount diving is gaining in popularity. If you’re diving a rebreather then a bailout system is de rigueur. And then there’s the consideration of gases: air, oxygen, nitrox. Do your homework but know that the selection process is made easier by consulting a dive shop professional.

Phew! But don’t forget valves? Will that be a yoke or a DIN?